Atomium Active Gasoline - oil additive for new gasoline engines, for restoring compression, power and eliminating oil consumption

Engine oil additive for restoring engine performance characteristics: compression, power, acceleration, effective fuel consumption, as well as for extending the wear life and protection in emergency situations. It will get rid of oil extra usage and engine smoke. The compound is designed for the treatment of gasoline and gas engines (LPG, CNG) of passenger cars with a mileage less than 50,000 kilometres. Suitable for all engine types and designs, including turbocharged and non-turbocharged.

Effects of application

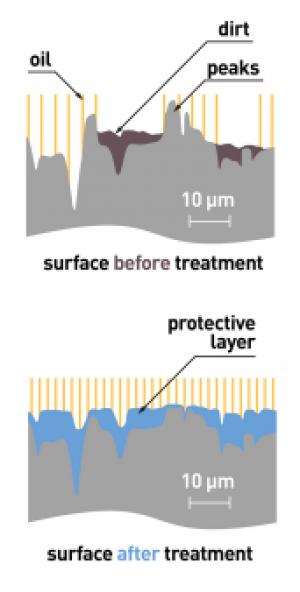

Under the influence of tribo-compound, a protective metal layer is formed on the worn parts, which is able to hold the engine oil film more firmly.

This allows you to solve the following tasks

Due to its structural features, the protective layer has increased microelasticity (it is deformed in a collision and then restores its shape, instead of being destroyed) and microhardness (it is not destroyed when loads from wear particles occur).

A denser oil film on the surface of the layer also reduces the direct contact of parts, withstands increased thermal and mechanical loads.

All this allows you to reduce engine wear, especially during long downtime in traffic jams, when the oil is overheated and liquefied, when maneuvering at low speeds or their sharp set, when oil starvation occurs.

Treated surfaces are able to retain the oil film during prolonged downtime. This makes it easier to perform the first turns and prevents increased engine wear during oil starvation at the start-up, which is especially important at a negative ambient temperature.

Due to its structural features, the protective layer has increased microelasticity (it is deformed in a collision and then restores its shape, instead of being destroyed) and microhardness (it is not destroyed when loads from wear particles occur).

A denser oil film on the surface of the layer also reduces the direct contact of parts, withstands increased thermal and mechanical loads.

All this allows you to reduce engine wear, especially during long downtime in traffic jams,when the oil is overheated and liquefied, when maneuvering at low speeds or their sharp set, when oil starvation occurs.

The oil film, held on the protective layer due to its structural features, is able to protect the engine from scuffing and jamming in the event of a sudden drop in oil pressure.

This allows you to avoid breakage if the oil loss or pressure drop was not noticed immediately. In addition, in some cases (depending on the design of the specific engine), this allows you to gently drive the car to the service station on your own.

The protective layer restores the density of the sleeve – ring – piston groove Assembly. This improves oil removal from the cylinder walls and reduces its fumes in the combustion chamber, especially at high engine speeds.

If the oil consumption is due to other reasons: "hardened" oil seals or destruction of oil-removing caps, tribo-compound will not be able to solve this problem.

Restoring and equalization of compression provides a more complete combustion of fuel, reducing losses when gases break through.

The dense oil film expands the hydrodynamic friction zone, which reduces friction losses. While maintaining the driving mode, this reduces fuel consumption by 6-8% for vehicles with high mileage. In new cars, it allows you to avoid increasing fuel consumption by significantly slowing down the wear process.

The protective layer speeds up and facilitates the work-in of parts. The new engine optimizes friction gaps faster, reduces the number of contacts on the surface of parts, normalizes compression, and the engine runs evenly and smoothly. This reduces noise and vibration when the engine is running.

HOW TO USE IT

Full treatment will require two bottles of the composition. It is added to the oil filler neck. It does not require any special knowledge or tools.

Adding the compound to the engine oil can be performed by any car owner on any passenger car independently. However, it is important to pay attention to the instructions attached to each bottle of the compound, so that it works as effectively as possible.

The standard treatment procedure is following:

- A bottle of the compound is added to the oil about 1000 kilometres before the planned regular oil change.

- Another bottle of the compound is added after replacement to the fresh oil and works there throughout the entire inter-service run.

HOW IT WORKS

Under the influence of tribocompound, a protective metal layer is formed on the friction surfaces of parts, which is able to hold the engine oil film more firmly. This layer significantly reduces the wear rate of parts even under high loads and oil starvation, which allows you to maintain the engine's rated characteristics for 70.000 – 90.000 kilometres of mileage.

Tribotechnical compound contains particles of the active mineral. When they fall into the zones of local contact surfaces, where there is a high local pressure, and the temperature exceeds 1000 C – mineral particles change the flow of friction processes. The surface of the part is able to "capture" metal microparticles that are in the lubricant. Gradually, a solid metal protective layer is formed on the entire worn surface, which is characterized by a porous structure with a large number of micro-depressions. The particles of the mineral itself remain in the oil and continue to have the necessary effects on other areas.

The micropores of the protective layer are filled with oil, which forms a continuous film on it due to surface tension forces. This oil film is never completely separated from the surface of the part, does not run off, even with a long idle time. The protective layer itself can withstand heavy loads due to increased microhardness and microelasticity compared to the original factory surface.

Restoring the shape and more effective lubrication, allow the parts to perform their functions as it was laid down in the engine design, which leads to the restoration of the performance characteristics of all friction units.

Additional info

Look also:

Atomium Aprohim™ SGA fuel additive gently cleans fuel equipment, lubricates it, protects it from corrosion and prevents the formation of sludge.

Oil additive to restore working characteristics of mechanical gearboxes of all types. It is also suitable for robotic gearboxes as they use the same type of torque transmission mechanism.

Removes kicks and jerks Transmission oil additive - AGSB (80 ml) is designed to protect against wear, extend the life and restore the characteristics of automatic gearboxes, including variators, of any type and with any type of transmission oil.

Long-term flushing ATOMIUM APROHIM™ is designed to clean the internal surfaces of the engine from long-standing deposits, removes black sludge and other contaminants and deposits.

Oil additive for restoring characteristics of diesel engines with mileage more than 50.000 kilometers. increases compression, power, acceleration, reduces fuel consumption.