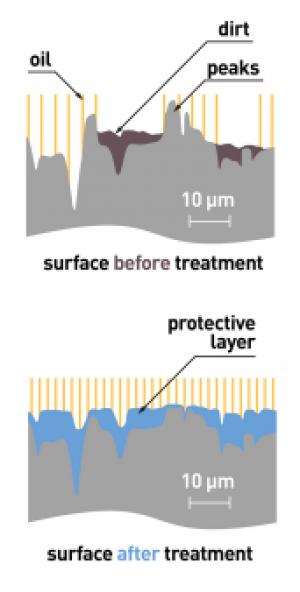

HPFP fuel additive for pump unit contains special active minerals. Micro particles of the mineral are moved throughout the system by fuel flow and particularly get to the pump plunger area. There under high pressure and temperature mineral releases ferrum which is being attached to the worn plunger surface. It sufficiently improves plug-to-sleeve fit and prevent fuel backflow.

This allows you to achieve the following effects:

- The outlet pressure is restored. With minimized fuel backflow the pump provides an output pressure within nominal ranges for different operating modes. This ensures the normal flow of fuel and correct injection to the combustion chambers.

- Noise and vibration of inline and distribution pumps are reduced. Restoration of the optimal coupling of the plunger pairs reduces vibrations and consequently noise during pump operation;

- Engine power is increased. Restoration of the fuel supply leads to better fuel combustion and thus to an increase in power while reducing fuel consumption by 3-5%.

- The emission of harmful CO and CH emissions is reduced by up to 50%.

- The service time of the pump may be prolonged bу 2-2,5 times.

HPFP fuel additive is designed to restore the performance characteristics and extend the life of high-pressure fuel pumps of diesel engines of any design:

- Inline fuel pumps;

- Distribution fuel pumps;

- Mainline fuel pumps in Common Rail systems;