Atomium Active Plus -oil additive for diesel, gasoline, gas engines with any mileage, for restoring compression, power and eliminating oil consumption

Tribotechnical compound is an engine oil additive aimed to restore engine performance parameters: compression, power, acceleration, effective fuel consumption, as well as to extend the engine life span and prevent breakdowns in emergency situations. Compound is designed for all types of engines: diesel, gasoline, gas (LPG, CNG) and treatment to be used for passenger cars with any mileage as for new cars with mileage < 50.000 km., as well as for big mileage engines > 50.000 km. Suitable for all engine types and designs, including turbocharged and non-turbocharged ones.

Tribotechnical compound alters friction process of metallic surfaces. It does not react with motor oils and their packages of chemical additives, does not change their properties and characteristics.

Effects of application

Atomium compound creates special conditions in areas of friction which leads to building up a protective metal layer. It covers worn surfaces, optimizes friction clearances, and retains dense oil film.

This allows you to solve the following tasks:

Restoration of the cylinders’ shape and a dense oil film on their surface seal the gaps between the compression rings and the cylinder walls. This prevents the breakthrough of gases and as the result increases compression and levels it among cylinders. Treatment with tribo-compound can not make the compression higher than the nominal level defined for this specific engine which makes the use of the composition safe.

Restoration of worn cylinders and piston rings is in fact the only stable and safe way to improve the tightness of their mating. It makes Atomium compound one of the best additives for low compression cases.

To stop engine oil burning or significantly reduce it

Treatment with the Atomium compound improves the mobility of piston rings (by cleaning up piston grooves) and narrows friction clearances between them and cylinders. This makes ring work more efficient and improves oil removal from the cylinder walls. Less oil gets into the combustion chamber and burns out there, especially at high engine speeds. Restoration of worn surfaces is a kind of “natural” way to fix oil burning root cause. There are additives for engine burning oil which are focused exactly on this problem. The Atomium compound proposes a decrease in oil consumption just as one positive effect in the row of others.

Remember – there might be other reasons for oil burning, for example - "hardened" valve stem seals. The most noticeable symptom of it is bluish smoke in the exhaust after an idle period. The tribotechnical compound is inactive with rubber details and unable to restore their functionality.

The level of motor oil may also constantly go down in case of oil leakage. The most often reasons for it – cracks in the oil pan or even engine block as well as damages gasket. In these cases, you may easily find out leakage traces outside the engine or on the road under the car. If there are any you need urgent help from a professional car mechanic.

Noisy lifters and constant tapping sound from the engine valvetrain is a well-known symptom often named as “tappety engine”. It is the result of tappet plunger wear especially in case of low oil pressure and lack of lubrication over large mileage.

The protective layer created by the Atomium compound restores the shape of the plunger surface, optimizes the clearances, which prevents oil breakout and normalizes its pressure inside the mechanism. This ensures the normal work of the unit and stops tappet or lifter noise.

Note – Atomium compound is not a valve cleaning additive. Other products should be used to remove soot from the combustion chamber.

To reduce engine noise and vibration levels

There may be various reasons for a strange regular noise and vibrations of the engine. Not all of them may be fixed with an additive for engine noise. However, the most frequent cause is wear. It widens friction clearances which may lead to an iron “clunging” sound at engine start-up. It may lower compression in some cylinders, reduce the power of stroke and break the overall engine balance, so it starts to tremble.

Restoring and equalizing the compression on the cylinders with the Atomium compound (as this was explained before) leads to the smooth operation of the engine. In addition, a thick and permanent oil film softens the contacts of metallic parts. All this allows to reduce or completely stop engine noise and vibrations.

The drop in oil pressure may be caused by an overall lack of oil in the system or by wear of the oil pump.

Restoring of the friction surfaces brings back outlet pressure of the pump to a nominal level and thus solves the problem.

Restoring and equalization of compression provides better combustion of fuel. Thus less fuel is needed for the same amount of energy.

Also, the dense oil film expands the hydrodynamic friction zone, which reduces friction losses by almost 50%. You may expect that engine treatment with the Atomium compound may reduce fuel consumption by 6-8% while you maintain your regular driving mode. The exact number depends on the initial state of your car and its mileage.

Note – Atomium compound is not a fuel additive, it doesn’t change fuel properties and neither changes combustion regimes.

To increase engine power and acceleration

The normalization of compression provides a nominal power output of the engine. It is especially noticeable at acceleration when you need to raise up revs abruptly.

To get rid of the smoke from the exhaust, reduce its toxicity.

Recovery of compression and optimization of gaps in the cylinder-piston group ensures high-quality fuel combustion and reduce oil fumes. This reduces the content of unburned fuel particles and oil combustion products in the exhaust gases, which reduces their smoke and toxicity.

In addition to the solution of actual problems, the use of tribo-compound allows you to achieve preventive effects:

The oil film retained by the protective layer on friction surfaces never flows down even during long idle periods. So the very first piston movements (as well as movements of other engine parts) at start up happen lubricated. It sufficiently reduces the wear of the engine. It is especially important in the cold weather when oil thickens in the pan and it takes more time to deliver it to the different engine sections.

To protect the engine from wear at high loads.

Due to its structural features, the protective layer has increased microelasticity (it is deformed in a collision and then restores its shape instead of being destroyed) and microhardness (it requires more load to be destroyed). A denser oil film on the surface of the layer also reduces the direct contact of parts, withstands increased thermal and mechanical loads.

All this allows you to reduce engine wear. It is especially important for driving in traffic jams when the oil is overheated and liquefied due to the lack of cooling. And also at low speed maneuverштп when oil starvation occurs due to low pressure.

The oil film, held on the protective layer due to its structural features, is able to protect the engine from scuffing and jamming in the event of a sudden drop in oil pressure.

This allows you to avoid breakage if the oil loss or pressure drop was not noticed immediately. In addition, in some cases (depending on the design of the specific engine), this allows you to gently drive the car to the service station on your own.

SIGNS OF ENGINE WEAR

There are various signs of critical wear of engine components. As a rule, increasing wear is shown up by a decrease in engine dynamics, an increase of average fuel consumption in the same driving modes.

The following are some of the most common signs of wear and tear, in which the treatment of the engine with tribo-compound can significantly delay the need for repair:

There is a sound of "iron clang" when starting the engine

Due to wear of the cylinder walls, the gaps between them and the piston rings widen.

When starting the cold engine the gaps have not yet decreased due to the thermal expansion of the parts, the piston can make transverse movements accompanied by a shock. The rapid succession of blows merges into a general "ringing", the engine "rattles".

This is especially noticeable when starting in the cold weather when the gaps are widened even more. This indicates that the cylinder surfaces are very worn, and each such launch wears them even more.

There is constant blue smoke in the exhaust.

Blue smoke means that oil is constantly entering the combustion chambers, which indicates that there are widened gaps between cylinders and piston rings due to their wear.

Tribotechnical compound is able to restore worn surfaces, remove smoke, and reduce oil consumption.

The engine started to work louder, harder, and there was a vibration.

These signs may indicate that the compression balance is disturbed.

Pistons in different cylinders are pushed with different forces, which disrupts the uniformity of the engine. If this sign appeared suddenly and sharply drew attention to itself, it is possible that there was a breakage – for example, a piston ring burst. If the vibration and noise increased gradually, imperceptibly, then most likely this is the result of wear. In this case, the Atomium tribotechnical compound will be able to restore the worn surfaces.

HOW DOES IT WORK?

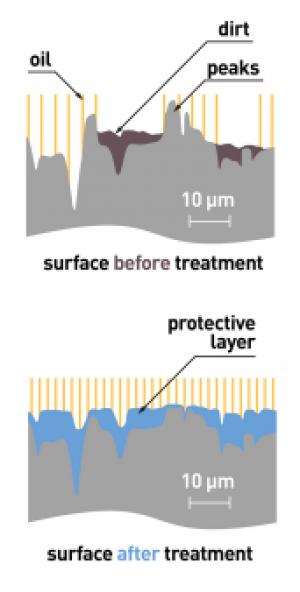

Under the influence of tribo-compound, a protective metal layer is formed on the worn parts, which is able to retain a dense oil film permanently.

Restored shape and dimensions + denser oil film on the surface -> normal operation of the engine units.

The Tribotechnical compound contains particles of the active mineral.

Getting into the zones of local contacts of friction surfaces with a temperature of more than 1000 degrees and high pressure the mineral particles activate electronic connections in the metal. It allows the surface to capture the metal from the engine oil, which is there as a product of engine wear. Gradually, a special protective layer is formed on the entire friction surface. It is stronger than a normal surface and can hold denser oil film due to its porous structure.

The micropores of the protective layer are filled with oil, which forms a continuous film under surface tension forces. Restoring the shape and more effective lubrication, allow the parts to perform their functions as it was laid down in the engine design, which leads to the restoration of the performance characteristics of all friction units.

Additional info

Look also:

To restore outlet pressure of a diesel high pressure fuel pump and prolong its service time. Suitable for all kinds of the fuel system including Common Rail.

"SDA (SDA)" is designed to restore and maintain the performance of diesel fuel systems, including Common Rail and "pump-injector" systems.

Atomium Aprohim™ SGA fuel additive gently cleans fuel equipment, lubricates it, protects it from corrosion and prevents the formation of sludge.

Oil additive to restore working characteristics of mechanical gearboxes of all types. It is also suitable for robotic gearboxes as they use the same type of torque transmission mechanism.

Removes kicks and jerks Transmission oil additive - AGSB (80 ml) is designed to protect against wear, extend the life and restore the characteristics of automatic gearboxes, including variators, of any type and with any type of transmission oil.

Additive for restoring the working surfaces of gears, reducing the noise and vibrations during their operation.

Oil additive to maintain performance characteristics and reduced wear of any type of engine after its complete treatment with other compounds of Active series. It should be added to motor oil after each (or at least each second) oil change.

Long-term flushing ATOMIUM APROHIM™ is designed to clean the internal surfaces of the engine from long-standing deposits, removes black sludge and other contaminants and deposits.

Atomium Aprohim™ SGA fuel additive gently cleans fuel equipment, lubricates it, protects it from corrosion and prevents the formation of sludge.

"SDA" is designed to restore and maintain the performance of diesel fuel systems, including Common Rail and "pump-injector" systems.