Full treatment process will require three bottles of the compound. It is added to the oil filler neck. It does not require any special knowledge or tools.

Adding the compound to the engine oil can be performed by any car owner on any passenger car independently. However, it is important to pay attention to the instructions attached to each bottle of the composition, so that it works as effectively as possible.

The standard treatment procedure is following:

- A bottle of the compound is added to the oil about 1000 kilometres before the planned regular oil change.

- Another bottle of the compound is added after replacement to the new oil and works there throughout the entire inter-service run.

- At the same time, it is more profitable to buy a set for a full processing cycle rather than separately bottle by bottle.

How it works?

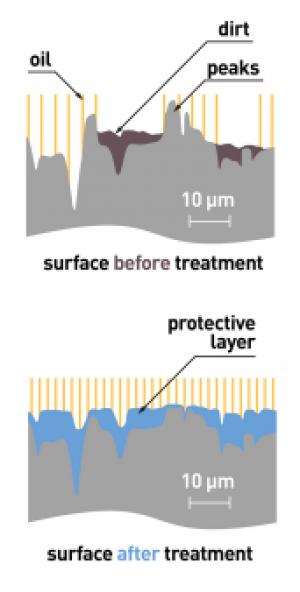

Under the influence of tribo-compound, a protective metal layer is formed on the worn parts, which is able to hold the engine oil film more firmly.

Restored shape and dimensions + denser oil film on the surface -> normal operation of the part.

Tribotechnical compound contains particles of the active mineral. When they get into the zones of local contact surfaces, where there is a high local pressure, and the temperature exceeds 1000o C – mineral particles change the flow of friction processes. The surface of the part is able to "capture" metal microparticles that are in the lubricant. Gradually, a solid metal protective layer is formed on the entire worn surface, which is characterized by a porous structure with a large number of micro-depressions. The particles of the mineral itself remain in the oil and continue to have the necessary effects on other areas.

The micropores of the protective layer are filled with oil, which forms a continuous film on it due to surface tension forces. This oil film is never completely separated from the surface of the part, does not run off, even with a long idle time. The protective layer itself can withstand heavy loads due to increased microhardness and micro elasticity compared to the original factory surface.

Restoring the shape and more effective lubrication, allow the parts to perform their functions as it was laid down in the engine design, which leads to the restoration of the performance characteristics of all friction units.

Antifriction additive for engine oil has a complex protective effect on most of the friction points in the engine. The compound is specially designed for cars with low mileage, but it is also suitable for cars after major repairs.

Solves popular problems:

- reduces fat and oil burnings;

- removes knocking, humming, noise, vibration in the engine;

- eliminates the wear of the crankshaft;

- protects the surface of cylinders;

- normalizes oil pressure;

- restores friction surfaces;

- improves the performance of the car's fuel systems.